![]()

Cowboy boots likely originated in 16th-century Spain. From there, they made it to Mexico, an essential part of the vaquero’s uniform. But it wasn’t until they wound up on the feet of frontier Americans that they became truly iconic.

As student of the Western, I thought it behooved me to know something about the legendary footwear that won the West.

Every American Should Own a Pair of Anderson Bean Bootswww.youtube.com

So I set out to find the most authentically American bootmakers in business.

It has been a humbling experience. I’ve discovered that I know very little about cowboy boots. I was originally going to feature Ariat Boots. I own a pair. They’ve gotten me through some vital moments: shoveling snow and trenching through floodwater yet also working perfectly at a wedding or funeral.

Let’s just say that after dealing with Ariat as a company, I no longer feel the same. It's a blessing in disguise, prompting me to venture into the unknown.

So I set out to learn about real cowboy boots. I polled a lot of people: What are the most American boots available?

I also discovered that I know a lot of people who know a lot about boots. My surveying led to three clear winners.

Third place was Lucchese. I spoke with someone on the company's media/PR team who was incredibly nice but in a somewhat off-putting way. Lucchese crafts breathtaking boots. But the price tag is enough to make you woozy. So to be fair, I can only afford to try them on. A few of the people I talked to said that Luccheses are the only boots they’ll wear.

The Duke wore them, and so did Gene Autry.

Tecovas came in second. Affordability, for one. $300 isn't outrageous for boots — good boots. I recently visited a Tecovas store in Austin, Texas. Quality gear. I never heard back from any of the company's publicists.

But one company earned the most votes by far: Anderson Bean Boots. A co-worker even connected me to Ryan Vaughan, the CEO. Before we began the interview, we prayed. It was lovely.

The conversation flowed in a blessed way. I walked away certain not only that he’s a good man and a God-loving man but also that he is at the helm of one of the more interesting small businesses I’ve encountered.

And by “small,” I mean that the company is devoted to crafting boots that will last a lifetime. Anderson Bean’s gorgeous footwear is truly handmade at the Rios Family factories in Mercedes, Texas.

Over the course of 30 minutes, Ryan and I discussed why he loves the boot business, the importance of retailers, and the demands of outfitting the Michael Jordans of horse training.

ALIGN: So I polled a ton of people to determine the best boot, and they overwhelmingly said, “Anderson Bean.”

RYAN VAUGHAN: Well, that's always music to our ears. It's nice when people can appreciate it, too, but that's obviously not what we're in it for. You bring up a bigger mission, and we always say we're not saving lives here, but we're trying to create opportunities. And that was actually felt at one point that I might be called to full -time ministry work and went and did a come-and-see weekend.

I figured out that the Lord said there's other ways that you can serve me, by plugging back into our community here and community service and then leading this company and trying to create opportunities.

I want a better way of life for everybody involved. Our core values, the first one is we will honor God in all that we do. And then we'll do the right thing when nobody is looking, and we go through the quality and supporting our retail partners. But we've got 235 lives that depend on what we're doing here, and families, and making sure that they can see what doing business the right way is. And hopefully the way I love my wife and love my kids and serve and [we] serve each other. So it's a tremendous responsibility.

There's a reason why there's not a lot of footwear manufacturing left in the U.S. You've got to do things the right way, and thankfully we've got people that respect it. We just had our human resource department put together a little list the other day. We've got 62 employees that have been with us for 10 years or more, and then you get up into the 40, and we've got three guys that have been with us 50 years or more. You get in, I think 12 in the 40 range, and that doesn't happen overnight. My father-in-law created an incredible foundation in this industry. So it's a heavy load to carry, but it's well worth it. Like I said at the beginning, when you follow God's will and go where he plants you, it's fun to grow there.

ALIGN: What does the title “Rios of Mercedes” mean, and how did that get started?

VAUGHAN: So the Rios family has been making boots since 1853. They started down in Mexico and came up to the border area of South Texas around the turn of the century. That was kind of when the border was getting secured. We had the U.S. military down here setting up Fort Brown and Fort Ringgold and Brownsville and Rio Grande City and policing to try to protect and try to create some opportunities for farming to come down to South Texas and take advantage of what we call the Magic Valley, which is a fertile valley area along the Rio Grande River here.

Zeferino Rios and his family moved up here to follow the money, and Zeferino settled in the town of Mercedes, which is the town where we still are, and his brother Abraham went up to Raymondville. So Abraham was Rios of Raymondville.

He really focused on making boots for the ranching families up in the cattle areas of Texas, and then Zeferino's family really focused on a lot of the dressier boots for all of the Midwestern folks that were moving down here to raise cotton and farm and vegetables and stuff. So that's the Rios of Mercedes. So yeah, a lot of people think it's Rio, Rio Grande River, but it's Rios of Mercedes.

ALIGN: That’s a classy name right there.

VAUGHAN: Yeah, any time I'm checking into a hotel and I tell them my email address, they always think I'm like a Mercedes-Benz dealer or something. (Laughs)

ALIGN: So are you from South Texas?

VAUGHAN: Yeah, from the Valley, my family's four generations down here. We were one of those families that came down here to farm. My great-grandfather was a cotton farmer, and they were up in the Dallas-Fort Worth area, further north than that, moved down. And my grandfather ended up buying into a chain auto parts store called Burton Auto Supply, which was a store that started in 1919 down here. And my brother is still running it. My dad and uncles took it over, and then my brother runs it.

ALIGN: How did you wind up at the helm of Anderson Bean Boots? Take me back to the beginning.

VAUGHAN: My family was in the auto parts business. So we didn't really do a lot of ranch-y stuff. We were more neighborhood kids, played baseball. We had a big old half-pipe ramp in our back yard. We skateboarded and played football and soccer and everything, basketball. And my brother started chasing a gal in high school. She was a barrel racer, and he got in the show and cattle. He was four years older than me and doing the show cattle thing.

And so after I got out of junior high and moved into high school, I followed right in his footsteps and started doing that, at the FFA show cattle deal, and did FFA leadership and district, and he chased his girlfriend up to Sam Houston State in Huntsville, and she was a barrel racer up there.

Anyway, we ended up both going through the ag program, ag business, and yeah, it was a great path to take.

I knew my now-wife since pre-K, so I grew up with her, and her dad was in the boot business, obviously. They've been doing it for 50-something years, and so I always was kind of around it and knew what they did, and we dated in high school and stuff. So I'm very familiar with the industry, and thanks be to God, God put me in the Western industry for good. Not where I expected I was gonna be, but boy, it sure is a perfect place for me.

ALIGN: Amen. That's the beauty of where God takes us.

VAUGHAN: Yeah, it's following His will, it brings peace, and exactly where thankfully I landed was exactly where I needed to be. And boy, that's what people always say. What do I love most about my job? And it's this industry that I get work in. I mean, mom-and-pop retailers all over the country. And for the most part, they're second, third generation. They're in small community, rural community areas that are super conservative, Christian background, morals, values, they stand up. You can't have a successful small business in a small community if you're not doing things the right way, because you're going to see those same people that you're selling to at church and at school and in the restaurants. And you've got to be doing things the right way. And thankfully, that's what a lot of our retailers build their business around.

ALIGN: Do you remember the first time you put on a pair of Anderson Bean boots?

VAUGHAN: Well, I actually had my first pair that my father-in-law gave me up here. They were actually some Rios Mercedes, and they didn't fit me very well because I didn't know what size I was wearing.

I worked at a sale barn in Huntsville, a cattle sale barn, all through college, and I was wearing Red Wings and who knows what other boots, and he finally gave me a pair of boots.

I felt pretty cool because I knew how expensive they were. I had never worn boots that fancy. But they were some old rejects out of the outlet store, and I've still got them up on my trophy wall.

ALIGN: So where does the name Anderson Bean come from?

VAUGHAN: In the mid-80s, my father-in-law, Trainer Evans, and his partner, Pat Moody, decided that they needed to build a boot that was a little bit more price-point-oriented but still domestically made. So they took the model of Rios Mercedes and just shortened up a few steps in the labor process and tried to streamline some of the options and made it a little bit more of a production-type boot.

My father-in-law, he's a fifth-generation West Texas feedlot cowboy. He said that the women who ran the ranch never got the praise and the credit they deserved. The ranching guys always used to go out and have the biggest dogs and kill the biggest deer and do all that, all the big cowboy stories. The women were at home raising them. He named it for his great-grandmother and his grandmother and his mother, Helen Anderson and Macie Bean.

And he just saw those women needed a little bit more credit and so named the boot company after them.

ALIGN: What makes Anderson Bean boots unique?

VAUGHAN: A lot of it starts with where we start. And that's really good relationships with our suppliers and that we try to treat our suppliers the way we want to be treated from our retailers. And that's being really loyal and paying well, giving them plenty of time to procure the materials and to do things the right way and just really build up relationships.

And so if you don't have good leather and good high-quality materials, the boots are not going to hold up, and so really building those relationships with the supplier, so that they know what our customers are putting the boots through to make sure that we have high-quality materials going into it. And that was one of the things that we started off with. We can build a cowboy boot in the United States ... made pretty much completely with materials to come in from other parts of the world, especially Mexico. [But] we decided that if we're going to build a boot in the U.S., we need to use U.S. suppliers.

We want to support the supply chain. A lot of the manufacturing moved out of the country, and it left a lot of our suppliers high and dry. And so we want to be really loyal to them. And thankfully they serve us really well.

So it starts off with the materials that we select, but then a lot of it is the construction, doing things the right way with a leather insole, a leather heel counter, and people go, “Well, what does that mean?”

It means that the boot molds to your foot. The more you wear it, the more it molds. Any time you get leather wet, the pores open up, and it just shapes around your foot. And then just using high-quality lining leather that rubs against your leg.

We use a latex water-based glue on a lot of the processes that breathes a lot better since it's water-based. A lot of other companies use a rubber cement that's cheaper and quicker. It creates a water barrier, a vapor barrier, so the boots get hotter.

In Texas and Oklahoma, in summertime, people go, ”My gosh, I'm going to wear a sandal, I'm going to the beach, it's so hot.”

Our customers kick it into full gear. I mean, that's when all of our team roping started up, all the high school finals, rodeos, and in fact, we've got the International Finals Youth Rodeo going on in Shawnee in a couple of weeks.

There's nothing better than a boot that you can take to the local cobbler, he can pull the sole off of them and knows how to rework them because they've got the guts in them. And so if you take decent care of a pair of leather boots, you can re-sole them four, five, six, seven times. And I mean, that boot, you may spend 350, 400 bucks on them, but 150 bucks every time you get a pretty much brand-new boot.

ALIGN: You often describe your boots as being useful. Like they're a tool. So what kind of beating can they take, and what does that mean for them to be a tool?

VAUGHAN: A lot of our core customer base is competitive horse show world, and so cutting horse, reining horse, reining cow horse, these are trainers. It'd be like if you were going to put Michael Jordan in a pair of cowhorses.

These guys are the top of their industry, and people pay them hundreds of thousands of dollars to train their horses. It's kind of like when you go to the Kentucky Derby, you watch it on TV. The trainers or the top notch, well, they're just training other rich people's horses for the most part, right?

But those guys and all of their staff are on horseback every day, training four, five, 10, 15, 20 horses. And so they ride, they wash those horses down, they're in the stalls, they're in the pens, they're in the manure, they're in the urine, they're back up on horseback, and especially the cutting horse guys, because those guys, they just ride and ride and ride and ride.

We always say it's best to kind of rotate your boots, let the leather dry. But these guys don't rotate. It's day in, day out. They're wet, they're dry, they're wet, they're dry. They've got spurs on them.

And so if we can build a boot that can hold up to that kind of wear and tear of a guy who uses that boot — they've got to compete in them. They've got to train those horses whenever it is. The competition is on; they've got to go. And so that's when we say that's a tool to let that guy be successful.

But then you get the real West Texas feedlot cowboys and these guys up in Montana and Dakota that are riding horseback — if you get a heel fall off your boot and you're in the middle of mountain country, there is no way to fix that. And so that's a tool that you've got to use, and you're riding up and down mountains and hills and in and out of streams and stuff. And so it's a livelihood for a lot of our customers that need those boots to actually survive and work.

And so I guess that's kind of the framework — whether we can build a boot strong enough for those guys and it'll last good enough for any normal guys like me and you.

ALIGN: Absolutely. Boots are so important. They’re what you wear to a wedding. They're what you wear to a funeral. They're what you wear in any really important event or even to the grocery store.

VAUGHAN: I think that's one of the things that brings you credit, whenever those guys are wearing the boots and the rest of the guys go, “Man, if that guy is wearing them, then" — you know, the same way with Michael Jordan in the Nikes.

That falls all the way down to the kids in sixth grade that are in the junior high team. They want a pair of those too because the best guys wear them, and that kind of works the same way with our world. And the other thing is, Oklahoma City, Fort Worth, Amarillo: There's a horse show event going on in those towns just about every weekend, and these guys come from all over the country, and if you've got enough money to be in this industry and you're flying in and bringing horse trailers and things, you're probably a pretty big wig in your community, and so whatever you take and see, hats and saddles and tack and boots from Fort Worth, Oklahoma, and Amarillo, and you go back to your community, everybody's watching you and seeing what you're wearing, seeing what you're coming back with, seeing what kind of saddle you've gotten, and so you create all these little disciples all over the country from these guys that are the big wigs in their community with the coolest, newest things, and hopefully the best quality as well.

ALIGN: So Anderson Bean boots also happen to look really good. What goes into that aspect of it?

VAUGHAN: We don't do any direct-to-consumer sales. So we drew a line in the sand that we are only going to support our retail partners that built this brand up. We've got about 10 sales reps that travel the country — in fact, we've got Dallas market going on right now at the World Trade Center in Dallas, and so retailers come and visit, and they see samples, they see swatches, and they design boots for their store.

What that gives our retailers is that they are the design team. Leather suppliers will come down, and guys that don't know us will go, “Well, where's your design team?”

I like picking out leathers, and my wife does a lot of stuff, but our retailers design them. So say you got Michael Kahn that has Dollar Western Wear in Lubbock, Texas. Sales rep Doc Watson will go out there and show him some different samples, and Michael says I've got a fresh batch of Red Raider kids, freshmen, coming in. He says I want a good black, smooth ostrich. I need a good price point for those kids, but I want a red top and I want white and black stitching with white side seam and trim, and those kids are gonna be dancing.

Well, he'll design it exactly for that customer and that price point. But when those freshman kids roll in and they go, “Wow. I'll check out those boots," and they go in the store and they go, "Let me go see if I can find them cheaper online.”

Guess what: He designed those things exactly for his store. So he gets to make a nice margin on it, which is what a retailer needs to be able to save, keep his doors open. And that kid gets something that's unique and different. And so what really drives the Anderson Bean creativity is always having something unique and different. And our suppliers know we pay good. They know we hit the market fast.

We don't have to go through all this research and development and testing and things. I mean, I'll see a new skin and — in fact, we had our suppliers from South Africa our ostrich suppliers here a few weeks ago, and they brought in a cool olive green ostrich leather. Well, guess what, I'm showing that to retailers the next week. We're getting orders on it, and we hit the market, and you start seeing what different colors and different finishes there are.

I don't want to say we're industry leaders because we're so smart or talented; it's just because we move fast and we listen. And that means listen to what our retailers are asking for. And we're not smart enough to figure out what's going to be hot in fall of 2027, the way all these fashion brands dictate kind of what's coming and what's new. But yeah, unique hides and skins are our name. I mean, we do carpincho, we do stingray, we do kangaroo, we do elephant, hippo. We do beaver tail. We do giraffe, zebra. I mean, a lot of exotics and everything.

ALIGN: I saw a shark.

VAUGHAN: Oh yeah, shark.

Broken Bow Country: Meet the 17-year-old behind a viral Western clothing brand

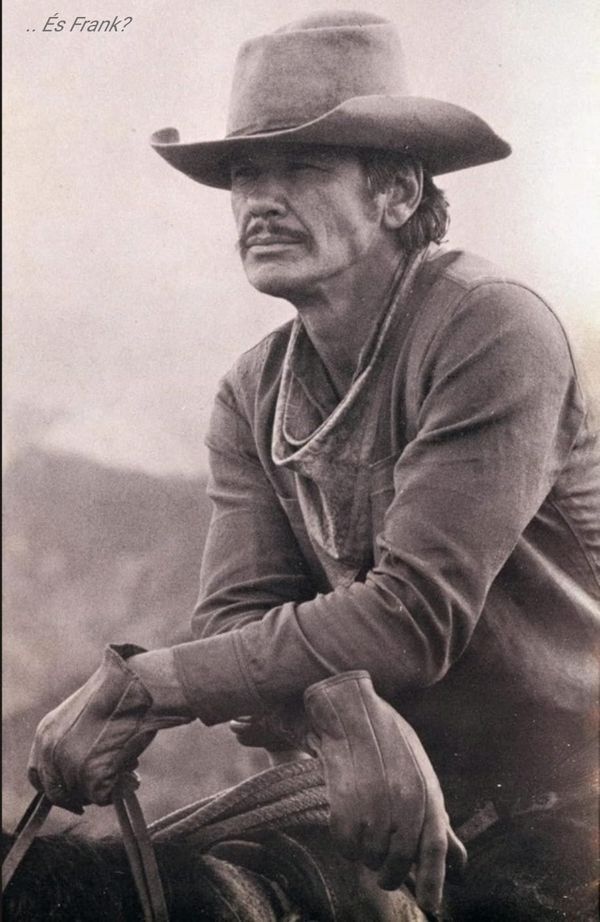

Broken Bow Country: Meet the 17-year-old behind a viral Western clothing brand Back to the old western | Charles Bronson as Chino in classic western film 'The Valdez Horses' in 1973 | Facebook

Back to the old western | Charles Bronson as Chino in classic western film 'The Valdez Horses' in 1973 | Facebook Kevin Costner & MW (@modernwest) on X

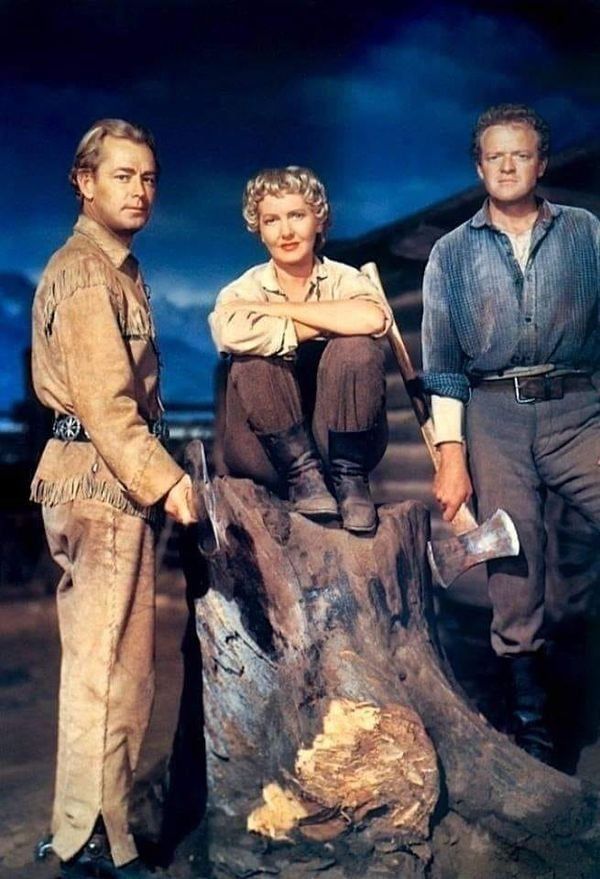

Kevin Costner & MW (@modernwest) on X Best cowboy movies forever | Alan Ladd, Jean Arthur, and Van Heflin in "Shane" (1953) | Facebook

Best cowboy movies forever | Alan Ladd, Jean Arthur, and Van Heflin in "Shane" (1953) | Facebook

The first chapter of Kevin Costner's new Western epic has a lot more to offer than its critical and financial woes suggest.

The first chapter of Kevin Costner's new Western epic has a lot more to offer than its critical and financial woes suggest.

In the wake of Oct. 7, the left's response makes much more sense when you consider the falsehoods they choose to believe about Israeli history.

In the wake of Oct. 7, the left's response makes much more sense when you consider the falsehoods they choose to believe about Israeli history.